Introduction

Rubber bands are used extensively by florists to hold bouquets together. More specifically, they are used extensively by flower growers to bunch flowers and produce. They are also used by florists to bunch bouquets or even as a delicate band used around the petals of flowers, especially tulips to keep them from opening during transit.

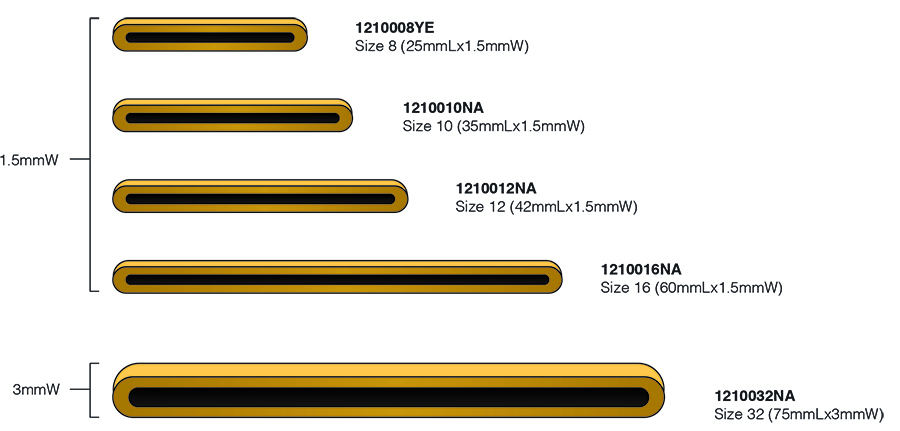

Size chart for Regular Rubber Bands available at Koch:

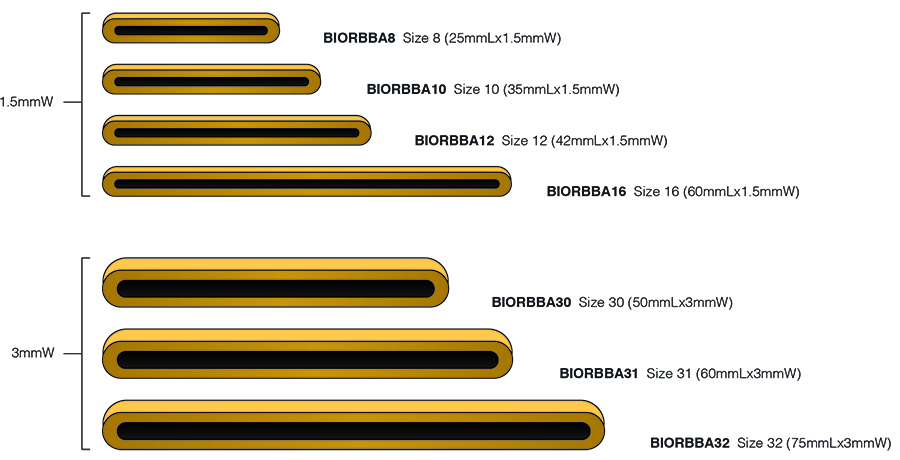

Size chart for Biodegradable Rubber Bands available at Koch:

Other colours, sizes and custom made orders

We welcome special enquiries and we can provide a customised service whereby we can produce anything that your company requires.

We have the ability to source natural tan, purple, white, blue, green, red and yellow rubber bands.

Please contact us here to enquire about availability and to place a custom order.

About our biodegradable rubber bands

- How do I measure a rubber band?

A rubber band has three basic dimensions: length, width and thickness. The length is half its circumference. Its thickness is the distance from the inner circle to the outer circle and its width is the distance from one edge to the other.

- What are rubber band packing details?

We currently stock 100gr and 500gr bags.

Bag Size Number of bags per carton 100gr bag 100 bags per carton 500gr bag 20 bags per carton

- What are rubber bands made from?

Rubber derives from plants that grow best in an equatorial climate. Rubber bands are made from organic rubber because of its superior elasticity. Natural rubber comes from latex, a milky fluid composed primarily of water with a small amount of rubber and small amounts of resin, protein, sugar and mineral water. An interesting note is most non-synthetic industrial latex derives from the rubber tree. Various equatorial trees, shrubs and vines also product the substance.

- What does the manufacturing process of rubber bands consist of?

There are 4 processes in making rubber bands. Below is the process broken up into 8 steps to help better understand each of the main processes.

Processing the natural latex

1. The rubber is collected from rubber trees on the rubber plantation and the first step is purifying the latex. It entails straining the latex to remove other constituent elements apart from rubber and to filter out impurities such as tree sap and debris.

2. Once the rubber is purified, it gets collected in large vats and is combined with acetic or formic acid. The rubber particles will then cling together to form slabs.

3. Each slab is squeezed between rollers to remove excess water and pressed into bales or blocks, ready to be shipped to factories.Mixing and milling

4. Rubber is shipped to a rubber factory. The slabs are machine cut into small pieces and using a Banbury Mixer, mix the rubber with other ingredients to increase or decrease the elasticity of the resulting rubber bands.

5. Milling is the next phase where the rubber is heated and squeezed flat in a milling machine.Extrusion

6. Now, the flattened rubber is cut into strips and while it’s still hot, fed into an extruding machines to force the rubber out in long, hollow tubes. Any excess that builds up around the head of the extruding machine is cut off, collected and placed back with the rubber in the milling machine.Curing

7. Tubes of rubber are forced over aluminium poles and because it’s brittle at this point, the rubber needs to be “cured” before it is elastic and usable. Poles are loaded onto racks that are steamed and heated to achieve this.

8. Finally, the rubber is removed from the poles and washed. Each tube is fed into another machine that slices them into finished rubber bands. Since they tend to clump together, only small quantities can be weighed accurately by machines.

- Are your rubber bands biodegradable?

Our BIORBBA range is made from natural latex rubber.

This product will eventually degrade under the right circumstances. For more information, contact your local council or waste management centre about how to dispose of the product properly.

- Do your biodegradable rubber bands have a smell?

All natural rubber products have a natural rubber smell. Cheaper synthetic substitutes do not smell and do not biodegrade.

- Where do your biodegradable rubber bands come from?

Our natural rubber comes from trees in Thailand where it is commercially produced in plantations. The plantations are sustainable and felled plantation trees are used for timber (Rubberwood) which has important uses in the furniture industry.

- Do your biodegradable rubber bands have an expiry date?

Due to the natural properties of the rubber, our bands last between 18-24 months.